Danfoss 068U4900 Thermostatic Expansion Valve Kit for Ice Machines R404A/R507 TUA Internal Equalization 1/4 x 3/8 ODF Kit Includes 068U1231 Valve and Orifices 1, 3, 5

Application: Universal Replacement for Ice Machines

Each kit contains: Exchangeable orifice thermostatic expansion valve. Selection of 3 orifice sizes. Copper fittings (2 elbows and 1 reducer). Copper bulb strap. Insulation tape. Installation guide

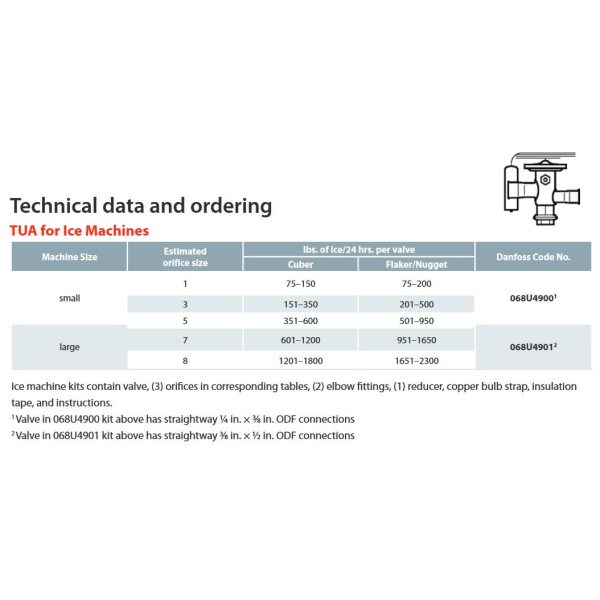

Replaceable orifice allows for capacity adaptations with a single valve and access to the screen for cleaning

Hermetic, laser welded, non-replaceable stainless steel power head

Robust stainless steel capillary tube and sensing bulb

Weight : 0.36 LBR

Volume : 0.01392506 FTQ

Model : 068U4900

UPC-EAN : 5702428851183

Replacement Thermostatic Expansion Valve For Icemaker Machines

These kits are designed with contractors in mind to help save time and money by providing a universal valve that can easily be adapted to replace most OEM specific TXVs. Two kits are available, each with a valve body and a selection of three orifice sizes, copper fittings (two elbows and one reducer), a patented bulb strap, and insulation tape

Selection and installation instructions

1. Determine the type of machine (cube, flake, or nugget), output of the machine in pounds of ice per 24 hours, and the number of expansion devices installed.

2. Divide the output in pounds of ice by the number of expansion valves.

3. Use the appropriate selection table below under Technical data and ordering to determine the correct orifice size for the ice output per expansion valve.

4. Adhere to start up and performance measurements as specified in the Instructions included with the kit. After the new valve is installed and the machine is back in operation, it is important to verify appropriate superheat performance. Cube ice machines typically start cycles with high superheat, which decreases as a harvest cycle approaches. A properly sized and adjusted valve will assure adequate capacity during all phases of the freeze cycle and positive superheat through the cycle. As the valve nears the end of the freeze cycle it is imperative that you accurately measure the evaporator superheat.

1. Inspect the ice for sufficient production.

2. Inspect the suction line just before the compressor for any frost that could indicate liquid flooding.

3. Measure superheat at the end of the freeze cycle.

4. If superheat is between 10F and 18F, ice is forming appropriately, and there is no sign of liquid flooding, the installation is complete.

5. If superheat is below 10F, increase superheat.

6. If superheat is above 18F, decrease superheat.

7. If after adjusting superheat you still see too low superheat or liquid flooding, please install the next smaller orifice and repeat this process.

8. If after adjusting superheat you still see too high superheat or insufficient ice formation, please install the next larger orifice and repeat this process.

If superheat adjustment is necessary, follow these steps:

1. Remove the cap with a 5/32 inch hex key.

2. Make superheat adjustments 1/4 turn at a time (1/4 turn = 1F).

-Turning clockwise increases superheat.

-Turning counter-clockwise decreases superheat.

3. Reinstall the cap.

Data sheet

- Product Feature

- Robust stainless steel capillary tube and sensing bulb

- Application: Universal Replacement for Ice Machines

- Each kit contains: Exchangeable orifice thermostatic expansion valve. Selection of 3 orifice sizes. Copper fittings (2 elbows and 1 reducer). Copper bulb strap. Insulation tape. Installation guide

- Hermetic, laser welded, non-replaceable stainless steel power head

- Replaceable orifice allows for capacity adaptations with a single valve and access to the screen for cleaning

- Robust stainless steel capillary tube and sensing bulb

- Weight

- 0.36 LBR

- Volume

- 0.01392506 FTQ

- Model

- 068U4900

- UPC-EAN

- 5702428851183